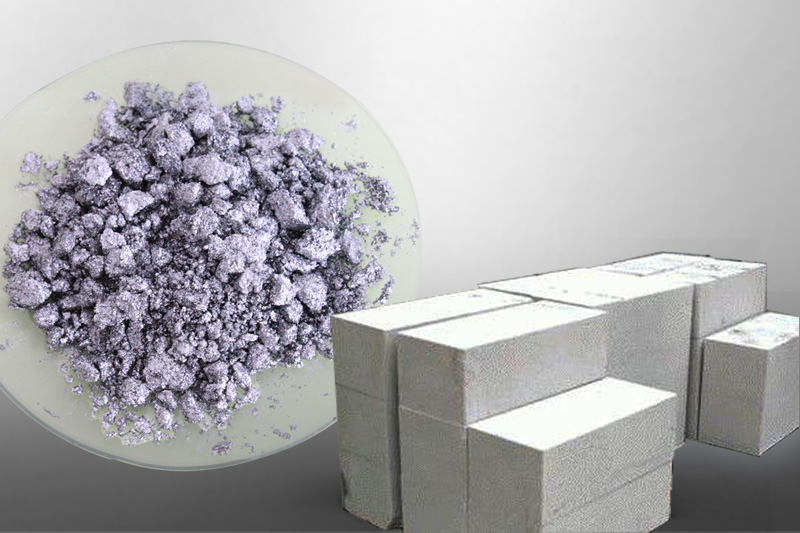

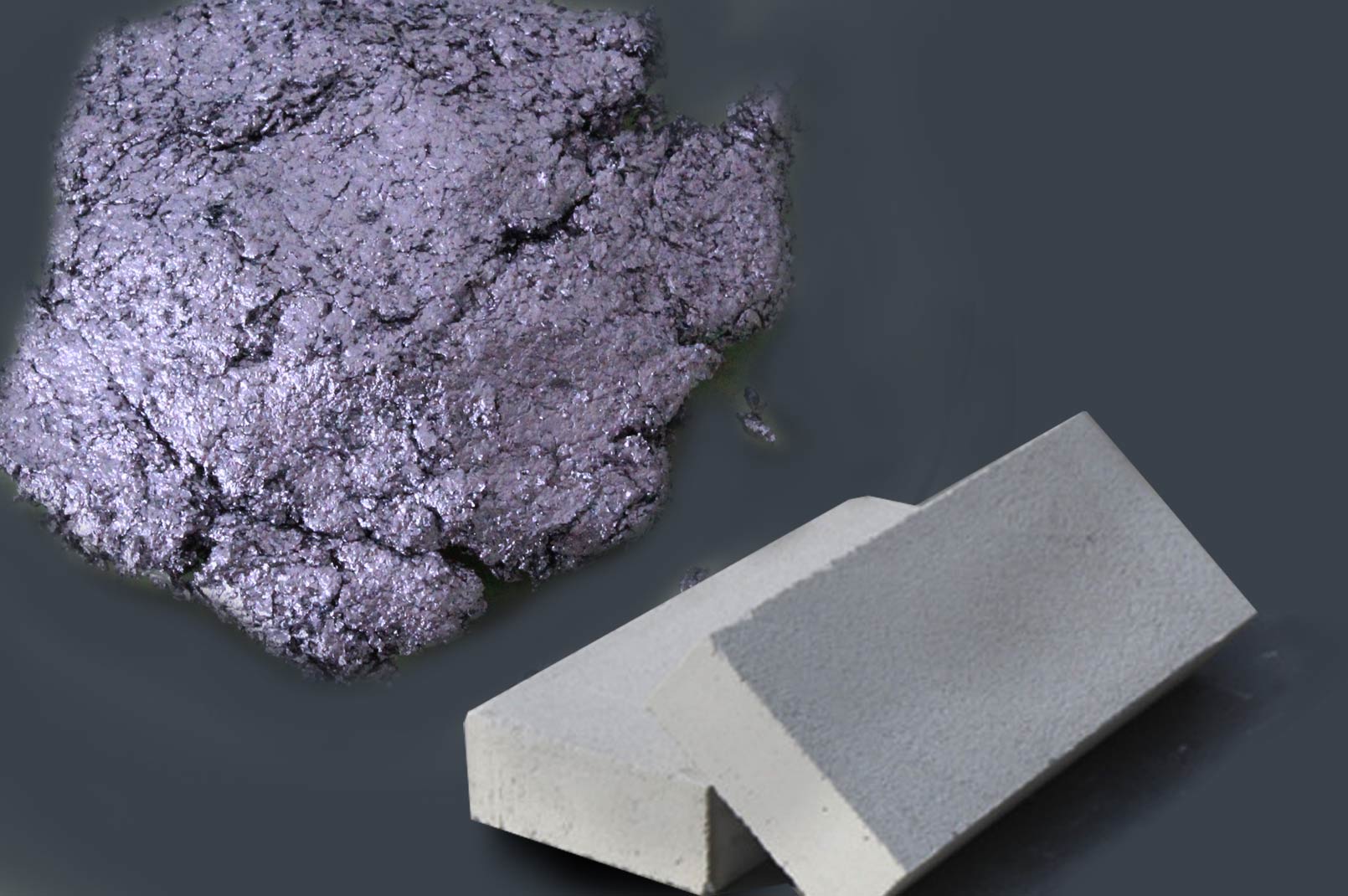

Aluminium Powder for SOLAR INDUSTRY

In order to improve the efficiency of the battery, we must consider reducing the recombination speed of the battery back surface and improve long-wave spectral response. Therefore, the quality of aluminum back field will directly affect the output characteristics of solar cells. The particle size of aluminum powder for aluminum back field formation and quality have a very important relationship. The smaller of the aluminum particles, the lower of the melting point, more easier to form a silicon-aluminum composite layer at a certain temperature and the silicon-based material, which is more favorable to the formation of the aluminum back field and improves the output characteristics of the solar cell.